Detrasher

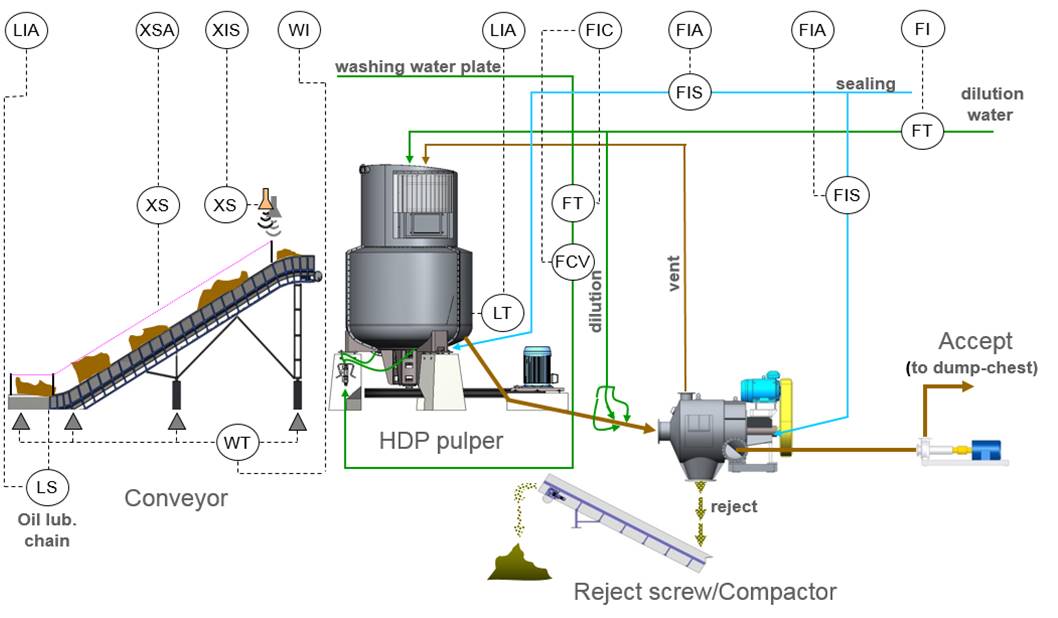

Detrashing machines are installed on high density batch pulper detrasher and the main function is to remove coarse contaminants and separated them from the fibers.

Contaminants include materials like :

- Printing inks

- Adhesives and glue

- Staples, pins, clips, pieces of wood, etc.

- Plastics and plastic films.

Contaminats are removed without being cutting in small size – avoinding further contamination of the downstream stock. Special rotor design and plate are installed.

Washed rejects are send to a trommel where rejects are separated from the water. Water is recovered and recirculated to the pulper.

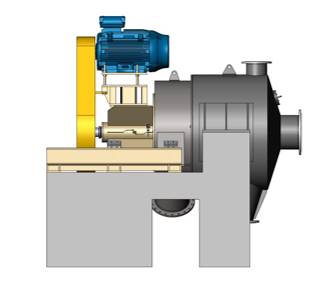

DETRASHING – batch application

DETRASHING – controls

Size 1 | Size 2 | Size 3 | Size 4 | Size 5 | ||

Volume | m3 | 1 | 2 | 3 | 4.5 | 6 |

KW installed | Kw | 30 | 55 | 90 | 110 | 132 |

Plate perforation | mm | 4-12 | 4-12 | 1-12 | 4-12 | 4-12 |

Rotor diam. | Mm | 910 | 1300 | 1500 | 1700 | 1900 |

Working consistency | % | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 |

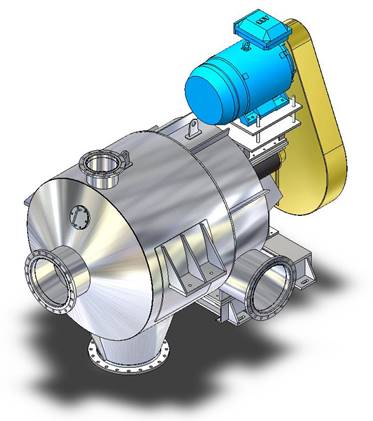

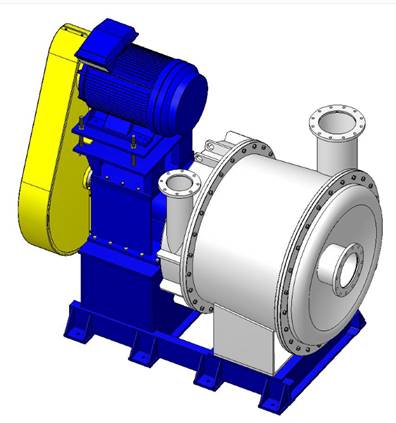

CONTINUOS DESTRASHING

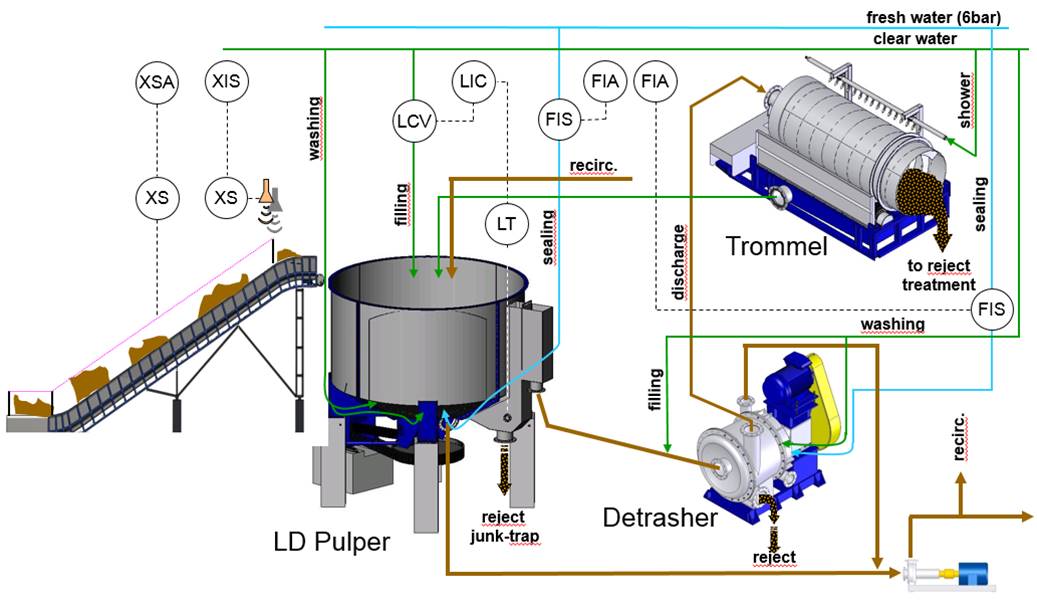

Continuos Detrasher are installed on OCC LD type pulper and the main function is to remove coarse contaminants and separated them from the fibers. Detrasher also increasing the pulping capacity as the accepred flow is sent forward.

Contaminants include materials like :

- Printing inks

- Adhesives and glue

- Staples, pins, clips, pieces of wood, etc.

- Plastics and plastic films.

Contaminats are removed without being cutting in small size – avoinding further contaminataion of the downstream stock. Special rotor design and plate are installed.

Washed rejects are send to a trommel where rejects are separated from the water. Water is recovered and recirculated to the pulper.

DETRASHING – batch application

CONTINOUS DETRASHING – controls

Size 1 | Size 2 | Size 3 | ||

Volume | m3 | 1 | 2 | 3 |

KW installed | Kw | 55 | 90 | 132 |

Plate perforation | mm | 6-12 | 6-12 | 6-12 |

Rotor diam. | Mm | 610 | 910 | 1100 |

Working consistency | % | 3-5 | 3-5 | 3-5 |